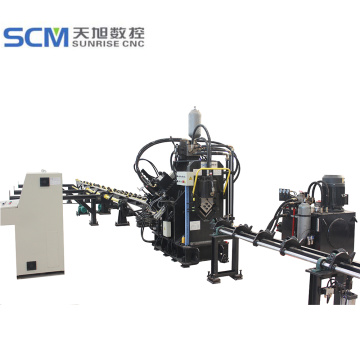

Ironworker Hydraulic Press Angle Production Line Efficiency

Basic Info

Model No.: TAPM1010

Product Description

Ironworker Hydraulic Press Angle Production Line Efficiency

Feeding speed and punching speed are very fast, greatly improve the production efficiency. For 50×50×4mm angles, it can process 9 to 10 tons per 8 hours.

The pressing angle device, NC infeeding carriage, Material supporting device, and clamping claws are Access to the national patent protection.

Adopt PLC module control, servo motor in feeding, with high efficiency, stable work piece precision.

The program function is perfect, already obtained the national patent, the program is more practical and more powerful.

Easy programming, can manual programming and also can use the program generated by lofting software.. It can read NC.1 files generated by TEKLA software.

All marking, punching and shearing in automatic completeness, all finished angles can be unloaded by pneumatic turnover device so as to lighten the working strength.

Marking unit adopts closed frame with good rigidity.

Single blade shearing, save raw material

The feeding conveyors use double linear guide, and the carriage is newest design, which improve the machine speed and accuracy.

This machine is mainly composed of transverse conveyor, rotating loading system, infeed conveyor, CNC infeed carriage, punching unit, marking unit, cutting unit, unloading conveyor, as well as hydraulic, electrical and pneumatic systems etc.

Specifications:

| Model | TAPM1010 |

| Functions | punching, marking, shearing |

| Angle size(mm) | 40×40×3~100×100×10 |

| Max. punching (dia. × thi.) (mm) | Circular holes Ф26×10 (Q345) Oval hole 22x50mm |

| Punching force (kN) | 1000 |

| Marking force (kN) | 630 |

| Shearing force (kN) | 1200 |

| Max. length of blank (m) | 10 or 12 |

| Max. length of finished (m) | 8 |

| Qty. of punch on each side (piece) | 3 |

| Qty. of marking group | 4 |

| Character size (mm) | 14×10×19 |

| CNC axis | 3 |

| Shearing mode | Single blade shearing |

| Angle feeding speed (m/min) | 80 |

| Programming mode | Lofting software or instruction program |

| Overall size(mm) | 25000×6500×2500 |

| Net Weight of machine(kg) | About 14300 |

| Working conditions: | ||

| Working environment: | Working temperature: | -10ºC ~ 40ºC |

| Voltage: | 380V, 50Hz, 3 Phase | |

| Fluctuation of voltage: | ±10% | |

| Air supply: | 1 MPa | |

| Processing precision (The allowable tolerance): | ||

| 1. | Two adjacent hole deviation of the same group | ±0.5mm |

| 2. | Two not adjacent hole deviation of the same group | ±0.7mm |

| 3. | Hole deviation of two adjacent group | ±1mm |

| 4. | Stadia (Distance from central of hole to edge ) | ±0.7mm |

| | ||

| No. | Name | Brand | |

| Main Electric Components | |||

| 1 | PLC | Japan YOKOGAWA | |

| 2 | Servo Motor | Japan YASKAWA | |

| 3 | Servo Driver | ||

| 4 | Business Computer | China Lenovo | |

| 5 | Photoelectric Switch | AUTONICS | |

| 6 | Low-voltage electrical parts(Switches,Push button, Breaker,Indicator light, Contactor switch and so on) | German SIEMENS | |

| 7 | Proximity Switch(N.O) | AUTONICS | |

| 8 | Proximity Switch(N.C) | AUTONICS | |

| 9 | Power Supply | China Aerospace | |

| Main Hydraulic Components | |||

| 1 | Hydraulic Valves | Italy ATOS | |

| 2 | Vane Pump | America DENISON | |

| Main Mechanical Components | |||

| 1 | Linear Slide | HIWIN | |

| 2 | Ball Screw | HIWIN | |

| Main Pneumatic Components | |||

| 1 | Punching Unit | Padding Block Cylinder | Japan SMC or AirTAC |

| 2 | Magnetic Switch | Japan SMC or AirTAC | |

If any part model is upgraded or changed, we promise to use same quality level part to replace it. Every change will be based on written form, which is agreed by each party.

Spare parts list of TAPM1010:

| No. | Name | Material | Qty. | Remark |

| 1 | Punch head | T10A | 1 set | Including installed in machine |

| 2 | Cavity die | T10A | 1 set | Including installed in machine |

| 3 | Upper blade | 9CrSi | 2 | Including installed in machine |

| 4 | Nether blade | 9CrSi | 3 | Including installed in machine |

| 5 | Punching mould | ZG45 | 5 | Including installed in machine |

| 6 | Punch head pole | T10A | 5 | Including installed in machine |

| 7 | Punching screw nut | 40Cr | 5 | Including installed in machine |

| 8 | Upper claw | T10A | 2 | Including installed in machine |

| 9 | Nether claw | T10A | 2 | Including installed in machine |

| 10 | Character box | T10A | 5 | Including installed in machine |

| 11 | Character(numbers+letters) | TAPM1010.5-12 | 2 sets | Including installed in machine |

| 12 | Proximity switch | Normal open | 1 | AUTONICS |

| 13 | Proximity switch | Normal close | 1 | AUTONICS |

| 14 | Photoelectric switch | 1 | AUTONICS | |

| 15 | O ring + Combination pad | 1set | ||

| 16 | Inner hexagon spanner | 1 set | ||

| 17 | 300mm adjustable spanner | 1 | ||

| 18 | 150mm Screwdriver (- /+) | 2 | ||

| 19 | Spanner for punch head | 1 | Manufacturer made | |

| 20 | Spanner for double nipple | 2 | Manufacturer made | |

| 21 | Standby paint | 1 pail | ||

| 22 | Operation Manual | 2 sets | ||

Packing list of TAPM1010:

| No. | Name & Specification | Qty. | Remark |

| | Main machine | 1 | |

| | Hydraulic pressure station | 1 | |

| | Electric cabinet | 1 | |

| | Operation cabinet | 1 | |

| | Blank material rack | 4 pcs | |

| | Overturn loading rack | 4 pcs | |

| | Infeed NC carriage | 1 | |

| | Loading conveyor | 14m | |

| | Unloading conveyor | 12m | |

| 10 | Spare parts | 1 box | Refer to Spare parts list |

| 11 | Spare part list | 1 set | |

| 12 | Operation Manual | 2 sets | |

| 13 | Attachment drawing | 2 sets | |

| 14 | Certificates | 1 set | |

| 15 | Packing list | 1 set |

Contact us if you need more details on Hydraulic Shear Angle. We are ready to answer your questions on packaging, logistics, certification or any other aspects about Sheet Metal Punch、Sheet Metal Machinery. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Punching Machine > Angle Punching Machine