H Frame Press for Deep Drawing of Auto Parts 1000t with Moving Bolster

Basic Info

Model No.: TT-LM1000T/LS

Product Description

Model NO.: TT-LM1000T/LS Controlling Mode: CNC Power Source: Hydraulic Pressure Stroke: 800mm Downward Speed: 400mm/S Min.Daylight: 400mm Table Area(Lr*Fb): 1400X1400mm Motor Power: 67HP Trademark: TAITIAN Origin: China Type: High-Speed punching machine Automatic Grade: Automatic Precision: High Precision Upward Speed: 310mm/S Max.Daylight: 1200mm Distance From Worktable to Floor: 500mm Press Dimensions(L,W,H): 4750X3600X7560mm Press Total Weight(Approx.): 53t Specification: TT-LM1000T/LS

h frame press for Deep Drawing of auto parts 1000T with moving bolster

Advanced Taiwan technology is adopted in TAITIAN press machines thanks to a senior Taiwan engineer who has been dedicating himself to research and development of hydraulic system for more than 40 years.

TAITIAN is manufacturing H Frame and Four Column structures deep drawing presses that are widely applied in different industries to make deep drawing components.

Characteristics:

1) The press is available up to 2000 Ton capacity as per customer's individual specifications and requirements. Each press is designed through Finite Element Structural Analysis and optimization to assure high strength and rigidity. High capacity press is preferred in H Frame structure.

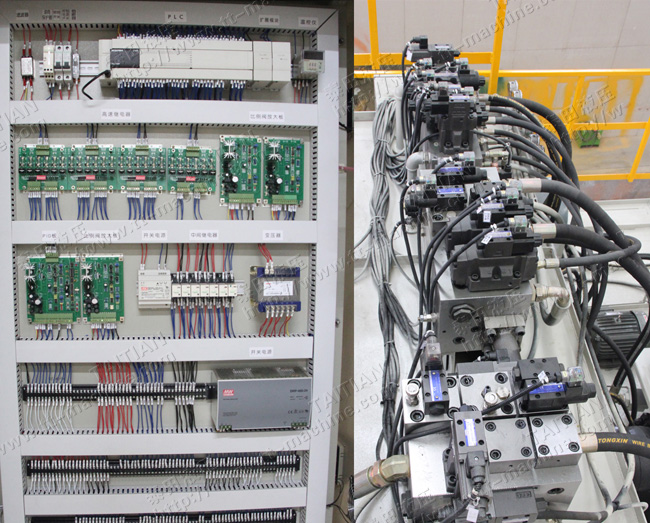

2) The press is equipped with advanced and systemized Taiwan hydraulic system featuring oil leakage resistance, anti-vibration, low energy consumption, low noise level and easy maintenance.

3) Eight sides of brass guide rails of full stroke length not only ensure high accuracy but also allow easy adjustment of slide leveling.

4) The press fully meets CE safety requirements. Two side locking cylinders lock the slide when it reaches top position. And two sets of light curtain sensors are fitted in the front and rear that will stop the machine when human body carelessly enters the working area.

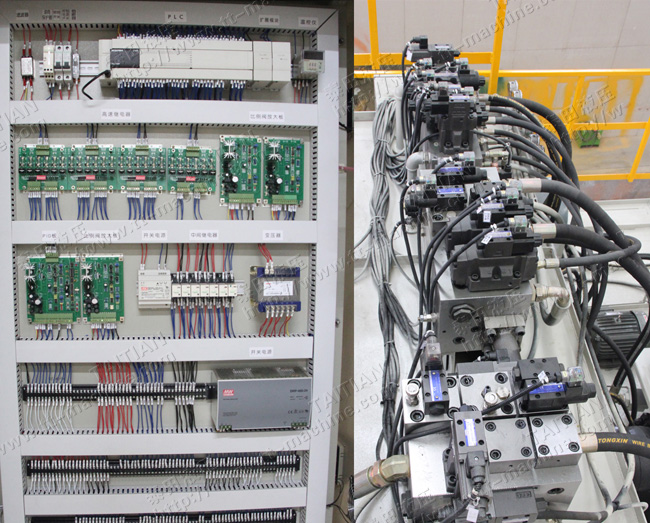

5) Mitsubishi PLC and 7 / 10 inch Taiwan Weinview touch screen make the machine easy for operation and specification adjustable.

6) Each press is manufactured under strict quality control management with good quality components from France, Japan, Germany, USA and Taiwan to assure the best performance and accuracy. H Frame Deep Drawing Press has been awarded with CE Certificate.

Optional:

1. Moving Bolster / Die Change Trolley

2. T-slots on slide or bolster

3. Stamping Dampers for shock proof while stamping

4. Ejectors on slide or bolster

Applications:

Deep Draw Press is applied in production techniques, like deep drawing, stamping, cutting, bending, flanging of metal sheet.

Particularly applied in the following industries:

1) Automobile Industry: Steel ring, vehicle body, chasis, axle housing, fuel tank, door, wheelbarrow tray and more.

2) Household Appliance Industry: Components for air conditioner, refrigerator, washing machine, microwave oven, electric cooker etc.

3) Kitchen Ware Industry: Stainless steel utensil, LPG cylinder, cooking bench, etc.

4) Aluminum Cookware.

Contact us if you need more details on H Frame Press. We are ready to answer your questions on packaging, logistics, certification or any other aspects about H Frame、Press for Deep Drawing. If these products fail to match your need, please contact us and we would like to provide relevant information.

h frame press for Deep Drawing of auto parts 1000T with moving bolster

Advanced Taiwan technology is adopted in TAITIAN press machines thanks to a senior Taiwan engineer who has been dedicating himself to research and development of hydraulic system for more than 40 years.

TAITIAN is manufacturing H Frame and Four Column structures deep drawing presses that are widely applied in different industries to make deep drawing components.

Characteristics:

1) The press is available up to 2000 Ton capacity as per customer's individual specifications and requirements. Each press is designed through Finite Element Structural Analysis and optimization to assure high strength and rigidity. High capacity press is preferred in H Frame structure.

2) The press is equipped with advanced and systemized Taiwan hydraulic system featuring oil leakage resistance, anti-vibration, low energy consumption, low noise level and easy maintenance.

3) Eight sides of brass guide rails of full stroke length not only ensure high accuracy but also allow easy adjustment of slide leveling.

4) The press fully meets CE safety requirements. Two side locking cylinders lock the slide when it reaches top position. And two sets of light curtain sensors are fitted in the front and rear that will stop the machine when human body carelessly enters the working area.

5) Mitsubishi PLC and 7 / 10 inch Taiwan Weinview touch screen make the machine easy for operation and specification adjustable.

6) Each press is manufactured under strict quality control management with good quality components from France, Japan, Germany, USA and Taiwan to assure the best performance and accuracy. H Frame Deep Drawing Press has been awarded with CE Certificate.

Optional:

1. Moving Bolster / Die Change Trolley

2. T-slots on slide or bolster

3. Stamping Dampers for shock proof while stamping

4. Ejectors on slide or bolster

Applications:

Deep Draw Press is applied in production techniques, like deep drawing, stamping, cutting, bending, flanging of metal sheet.

Particularly applied in the following industries:

1) Automobile Industry: Steel ring, vehicle body, chasis, axle housing, fuel tank, door, wheelbarrow tray and more.

2) Household Appliance Industry: Components for air conditioner, refrigerator, washing machine, microwave oven, electric cooker etc.

3) Kitchen Ware Industry: Stainless steel utensil, LPG cylinder, cooking bench, etc.

4) Aluminum Cookware.

Contact us if you need more details on H Frame Press. We are ready to answer your questions on packaging, logistics, certification or any other aspects about H Frame、Press for Deep Drawing. If these products fail to match your need, please contact us and we would like to provide relevant information.

Product Categories : Deep Drawing/Metal Stamping Press > H Frame Type

Premium Related Products

Other Products

Hot Products

Four Column Hydraulic Press (TT-SZ40T)1000tons/2000t Hydraulic Deep Drawing Press (TT-LM1000T-2000T)CE/Nr Standard Hydraulic Press Machine (TT-LM4000T)pneumatic press punching machine made in chinacnc amada hydraulic bending press brake machine bender60Tons C Frame Four-guide Single Column CNC Hydraulic Press Machinehot sale steel door hydraulic press machine pricesheet metal folder 5m, press brake 5miron sheet hydraulic guillotine shear machine 4mFactory Price Metal Cutting Machine / Hydraulic Shearing Machine 6x2500aluminium foil pan press machine 45tons with two cavityWE67Y metal plate press brake bender machineMetal Pipe Tube Embossing Machine Swaging Machine100w 150w 300w 500w cnc plasma laser cutting engraving machineHydraulic salt lick block pressing machine,cow salt licking brick making machineconstruction building diesel engine manual cement concrete hollow block brick making machine