CNC Busbar Cutting Punching Machine

Basic Info

Model No.: CNC-BP-30

Product Description

Function features:

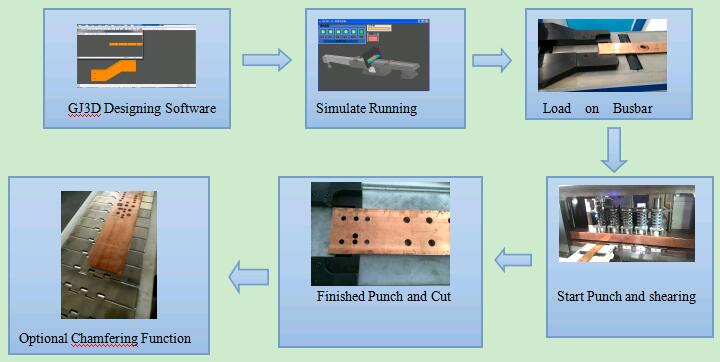

GJCNC-BP series CNC busbar punching & Shearing Machine is the computer-controlled equipment of high efficiency and high precision, specially used for busbar processing; Dies of punching, shearing are placed together in the storeroom of dies; It is capable of executing punching(round, oblong and other holes), shearing, slotting, round cornering and other processes; Automatic clamp switching can be achieved without manual intervention for longer busbars. Finished work pieces will be sent out through the conveyor. Such machine series can be used in combination with the CNC busbar Bending Machine to form an assembly line of busbar processing.

Advantages:

- 3D software--This is our independent patent in busbar processing, which can realize 3D automatic programming and dynamic simulation.

- Double clamps--Comparing other single clamp, double clamps can make processing more accurate and stable.

- Hydraulic system-- Piston pump (rather than gear pump) has large drive power and realize high efficiency.

- Main components--Imported, so the quality and service life can be guaranteed.

Technical parameter

| Technical parameter | |||

| Description | Unit | Parameter | |

| Press Force | Punching Unit | kN | 500 |

| Shearing Unit | kN | 500 | |

| Embossing Unit | kN | 500 | |

| X Max Speed | m/min | 60 | |

| X Max Stroke | mm | 2000 | |

| Y Max Stroke | mm | 530 | |

| Z Max Stroke | mm | 350 | |

| Stroke of Hit Cylinder | mm | 45 | |

| Max hit speed | HPM | □120 □150 | |

| Tool | Punching Mould | set | □6 □8 |

| Shearing Mould | set | □1 □2 | |

| Embossing Mould | set | □1 | |

| Control Axis |

| □3 □5 | |

| Hole Pitch Accuracy | mm/m | ±0.20 | |

| Max hole punch size | mm | Φ32( Thickness of Copper bar <12mm) | |

| Max embossing area | mm² | 160×60 | |

| Max Allowable sheet dimension(L*W*H) | mm | 6000×200×15 | |

| Total power | kw | 14 | |

| main machine dimension:L*W | mm | 7500X2980 | |

| Total weight | kg | 7600 | |

Packing details:

1) Applying Anti-Rust Oil

2) Covering with stretch film

3) Covering aluminum air bag

4) Vacuuming air bags

5) Boxing all the pallet

6) Loading to the container

Product Categories : Busbar Punching Machine